Welcome to Retooling Precision Machining Tech (TaiCang)Co.,Ltd.

ReaGold Precision Technology: Precision Machining Plan for Heat Exchange Tube Sheets

2024-06-21 09:49

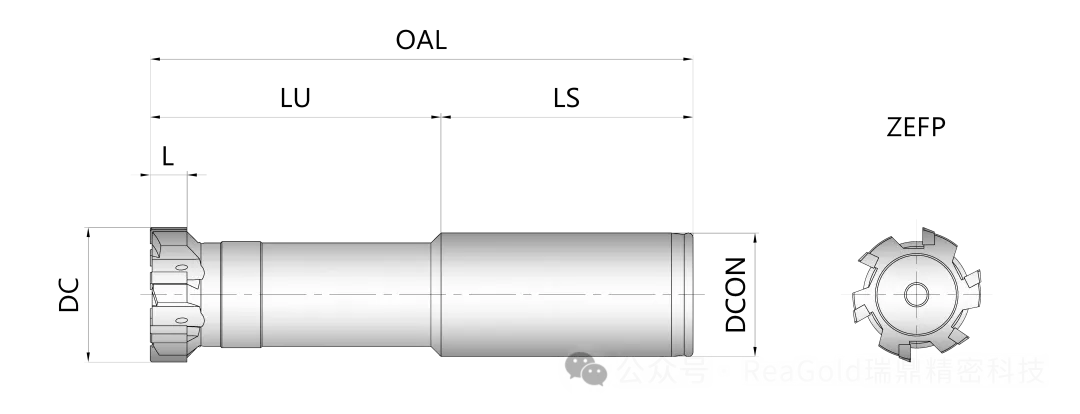

Machining Tools

Xueji®S Series

ReaGold standard finished product series ranges from 13.00mm to 40.00mm, integer diameter segment H7, carbide coated, cermet uncoated two types of finished products are in stock and can be delivered quickly.

- This series can also be customized with a full range of tools with a diameter range of 7.90-40.59mm and an accuracy of IT7.

- The cutter body has excellent fatigue resistance

- Achieve high-speed cutting with a roughness of up to Ra0.4

- Micron-level precision, no additional adjustment required, ensuring processing stability

- Unique cutting edge geometry design provides excellent processing performance

- Cutting edge can be repaired multiple times with low cost of use

- Built-in high-pressure cooling channel for cooling and lubrication, increasing tool life by more than 30%

Operating Condition

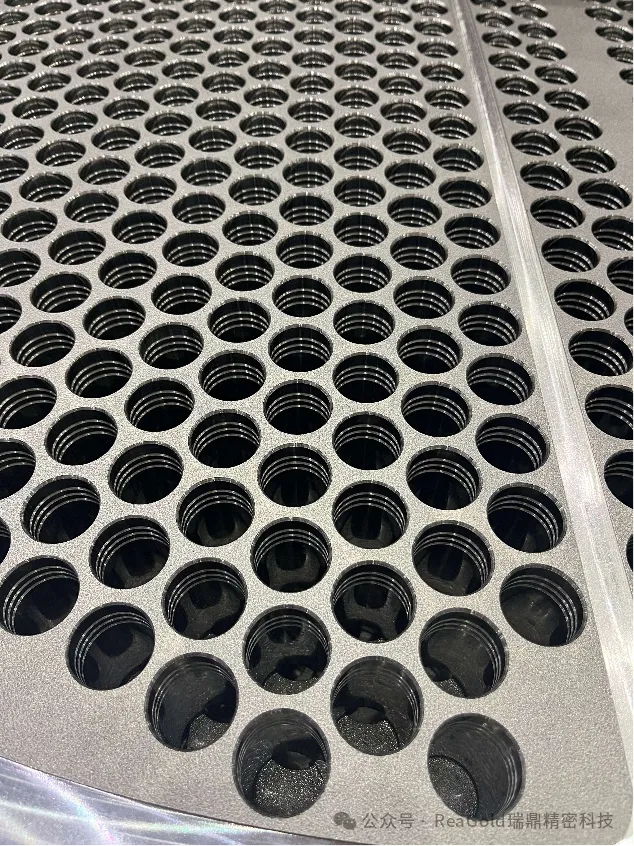

Workpiece: Heat Exchange Tube Sheets

Material of Workpiece: Alloy steel

Hardness: HB180

Main Spindle Power: 25kw

Toolholder (Spindle Interface): BT50

Processing Parameters

Aperture Tolerance:D25.7(+0.05/-0.04)

Cutting Speed: Vc = 145mm/min

Feed Rate: ap = 60mm

Cutting Feed Speed: Vf = 600mm/min

Cutting Depth: ae=0.15mm

Surface Roughness: Ra1.6

Life:1300hole

Comparison between the xueji S series and the Original Boring Tool Scheme

- The quality of hole wall processed by reamer is much higher than that of milling cutter

- Reamer does not need to be processed twice, and milling cutter needs to mill twice after 500 holes to ensure the quality of hole wall

- Hole milling cutter cannot process holes above H60mm, but reamer can. For holes below H60mm, reamer has obvious efficiency advantage

- The comparison of reamer and milling cutter life is as follows:

|

Heat exchange plate thickness |

Original solution (milling cutter) |

Xueji S Series Reamers |

|

60mm |

1300 holes |

2600 holes |

|

40mm |

1300 holes |

3900 holes |

|

20mm |

1300 holes |

7800 holes |

Combining relevant data and comparing under the premise of meeting precision requirements, the processing efficiency, life and finish of reamer are significantly improved, and it brings high-value hidden advantages, which meets the improvement requirements, meets the core needs of enterprises for long-term stable processing, increasing quality stability, reducing comprehensive costs, and improving comprehensive competitiveness in the industry.

info@reagold.cn

info@reagold.cn