Welcome to Retooling Precision Machining Tech (TaiCang)Co.,Ltd.

Showcase of the latest technological achievements of the Jingni i series

2025-04-18 09:08

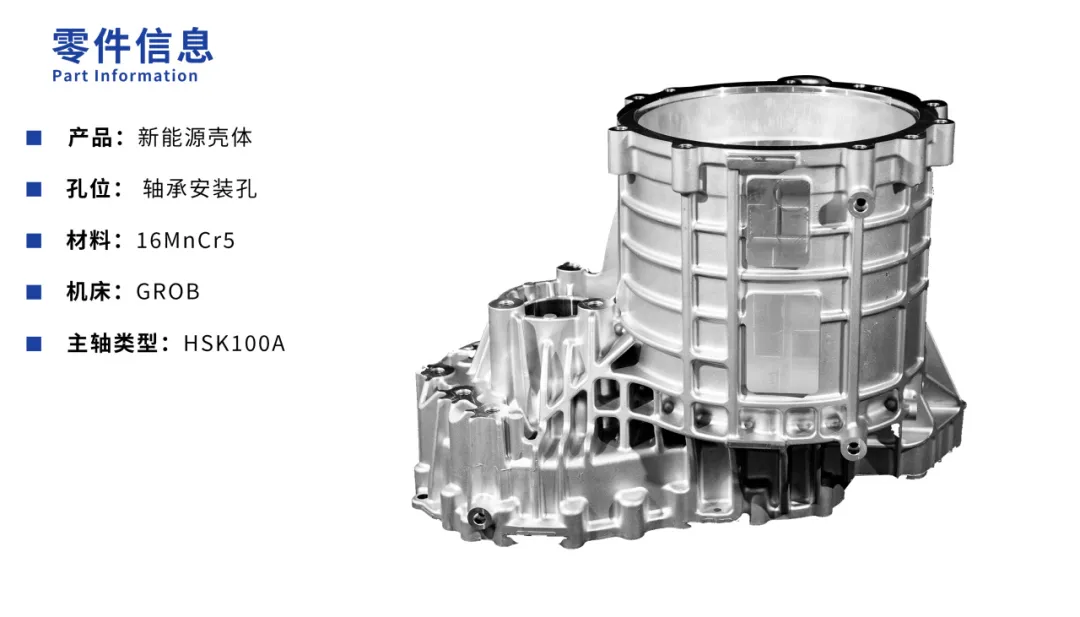

In new energy equipment, the bearing mounting holes are key components that ensure the stable and precise operation of the equipment. As the datum surface for bearing installation, its machining accuracy directly affects the bearing's mating quality and overall performance.

New Energy Bearing Mounting Hole

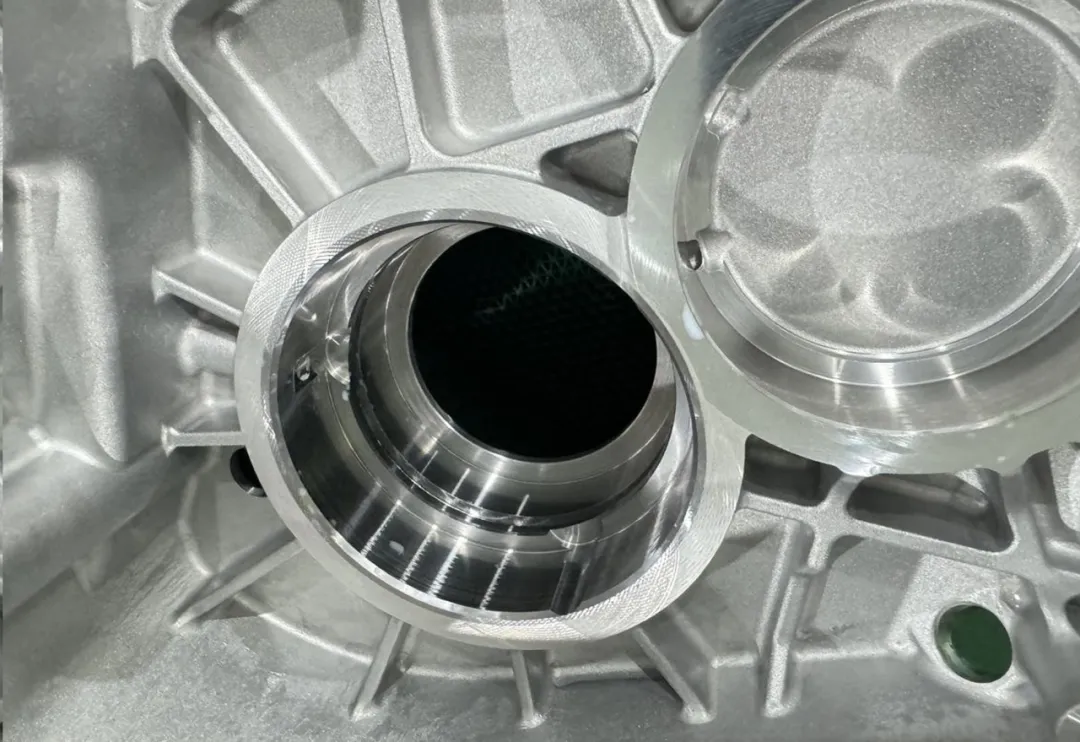

In new energy equipment, the bearing mounting hole is a key part that ensures the stable and precise operation of the equipment. As the reference surface for bearing installation, its machining accuracy directly affects the matching quality and overall performance of the bearing. High-precision bearing mounting holes can effectively reduce friction and vibration during equipment operation, improving transmission efficiency and service life. In addition, new energy equipment usually faces high-speed and high-load operating conditions, and the coaxiality and verticality of the bearing mounting hole are crucial, which can avoid operational deviations or equipment damage caused by errors. Therefore, precise processing and strict quality control are the basis for ensuring the effective operation of new energy equipment.

The processing of new energy bearing mounting holes puts stringent requirements on precision and stability, and the main difficulties are reflected in the following aspects. First, the mounting hole needs to achieve extremely high dimensional accuracy, tolerance matching, and coaxiality to ensure stable equipment operation; otherwise, it may lead to failures or shortened lifespan. Second, the processing materials are mostly high-strength alloys or lightweight materials, which are high in hardness and easy to deform, have poor machinability, and significant tool wear problems. In addition, the mounting hole is often located in a complex structure, and during processing, it is necessary to overcome spatial interference problems, which puts higher demands on tool selection and path planning. At the same time, how to ensure the consistency of each hole in mass production and avoid accumulated errors is also a core challenge in achieving high-quality production. These factors together increase the processing difficulty and place higher demands on technology and process levels.

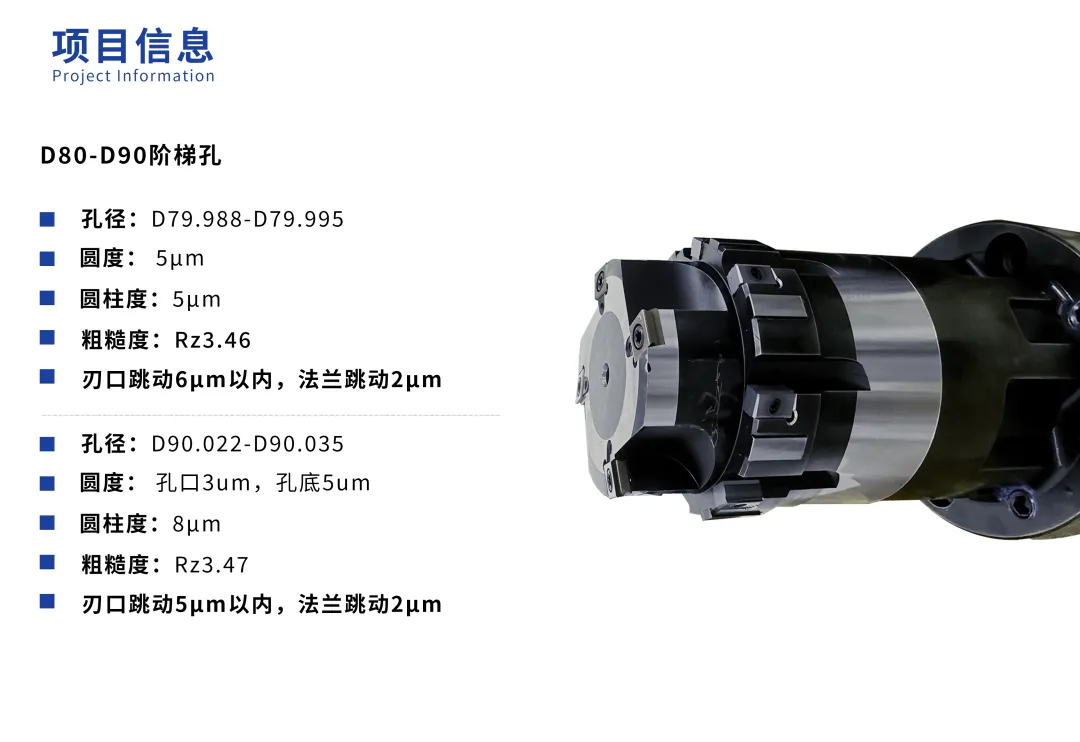

For new energy bearing mounting hole machining, ReaGold provides two effective solutions to meet different needs.

Brazed carbide cutter solution With high wear resistance and excellent precision, it is specially designed for high-hardness material processing. Its flexible customized structure can be optimized according to the hole diameter and material characteristics to ensure dimensional stability and processing consistency. This solution is especially suitable for workpieces with complex structures and strict tolerance requirements, and is the best choice for high-quality processing.

i-series guide bar cutter solution It adopts a replaceable blade design, making blade replacement convenient and greatly reducing maintenance costs and downtime. Equipped with a precision guide bar support structure, it ensures excellent coaxiality and hole diameter consistency, while also having excellent chip removal performance and low cutting resistance. This solution is particularly suitable for high-precision and high-efficiency mass production needs, providing customers with an economical solution.

ReaGold's two solutions each have their own advantages: the brazed carbide cutter is mainly characterized by stability and processing consistency, suitable for applications with strict precision requirements; the i-series guide bar cutter is characterized by flexibility, low cost, and high efficiency, making it an ideal choice for those seeking economy and efficiency. Whether customers focus on precision or cost-effectiveness, ReaGold can provide the perfect solution!

info@reagold.cn

info@reagold.cn